Product Description

112 CERA REPAIR is putty like consistency, high performance ceramic-filler modified epoxy compound for sealing, protecting

and repairing surfaces subject to erosion, corrosion and wear

Field Of Application

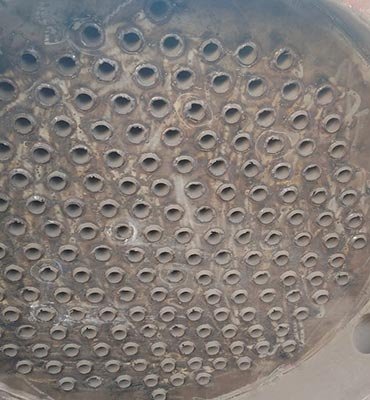

Seals and protects old as wells as new equipments exposed to erosive and corrosive abuses. Protects pump casings, impeller

blades, gate valves, water boxes, and fan blades; rebuilds heat exchangers, tube sheets and other water circulating equipment.

Details Of Kit

The kit is supplied with required quantity of part A and part B. For optimum performance, maintaining correct ratio of part A

and B is absolutely essential. Please do not use part quantities of part A and B. USE THE ENTIRE QUANTITY IN ONE

LOT. thinner may be used only for general cleaning.